Italy

Motorway embankment on soft soil “Catania – Siracusa”

Year: 2008-2009

Location: Sicily

Country: Italy

Volume: 150.000 m³ expanded clay 0-30 mm

Owner Builder: ANAS S.p.A.

Contractor: Pizzarotti Sp.A.

Designer: Pro.Iter S.p.A.

Problem / Solution

Near CT the motorway crosses an area with very thick soft soils (up to one hundred meter deep) where 5 bridges were designed and constructed on piles. The relative embankments were thirty five meter wide, and were problematic for the differential settlements between the bridges and the embankments.

Experience

The solution with expanded clay was chosen in order to limit the settlements over a layer of 100 m of soft soils. In one particular stretch of this highway, it was decided to make a traditional embankment (about 2.000 kg/ m³). The section in question until January 2014 has had settlements of 1,25 m. Even now these settlements continue in time.

Why expanded clay?

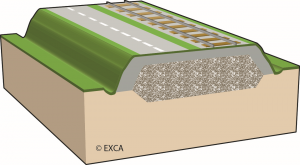

To limit the disturbance to the soil, it was decided to limit the embankment weight. The embankment load has been reduced by adopting a light embankment with compensation, by the use of alternating layers of 70 cm of expanded clay and 30 cm of granular material. The weight of this solution is approximately 1.000 kg/m3. Where embankments were higher it was also chosen to make superlight embankments. The superlight fill was made with steel pipes in order to occupy the maximum possible space between the ground level and the pavement. The space in between the pipes has been filled with lightweight concrete made with expanded clay. The total unit weight for the completed embankment, including pipes and concrete, is not larger than 300 kg/m3.

Problem/solution:

Near CT the motorway crosses an area with very thick soft soils (up to one hundred meter deep) where 5 bridges were designed and constructed on piles. The relative embankments were thirty five meter wide, and were problematic for the differential settlements between the bridges and the embankments.

Why LWA:

To limit the disturbance to the soil, it was decided to limit the embankment weight. The embankment load has been reduced by adopting a light embankment with compensation, by the use of alternating layers of 70 centimeters of expanded clay and 30 cm of granular material. The weight of this solution is approximately 1000 kg/m3.

Where embankments were higher it was also chosen to make superlight embankments. The superlight fill was made with steel pipes in order to occupy the maximum possible space between the ground level and the pavement. The space in between the pipes has been filled with lightweight concrete made with expanded clay. The total unit weight for the completed embankment, including pipes and concrete, is not larger than 300 kg/m3.

Experience:

The solution with expanded clay was chosen in order to limit the settlements over a layer of 100 m of soft soils. In one particular stretch of this highway, it was decided to make a traditional embankment (about 2000 kg/ m³). The section in question until January 2014 has had settlements of 1.25 m. Even now these settlements continue in time.

Key Issues: