Norway

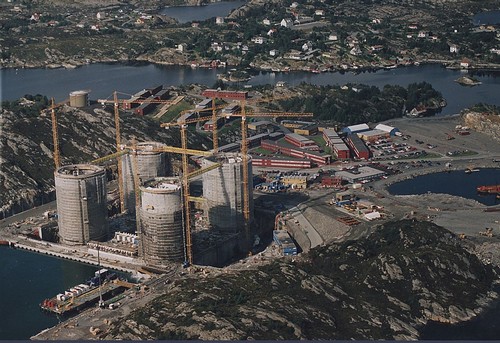

Heidrun Floating Oil-Production Platform

Year: 1995

Location: Norwegian Sea, Norway

Country: Norway

Owner Builder: Statoil

Contractor: Kværner Concrete Construction

Designer: Kværner Concrete Construction

Problem / Solution

The Heidrun floating oil-production platform was installed at a water depth of 345 metres in the Norwegian sea. Heidrun was the world’s first tension leg platform (TLP) with a concrete hull and represents a break-through for high strength lightweight aggregate (LWA) concrete as a building material in floating offshore platforms. Exposed to a harsh marine environment, the design life requirement for the structure is more than 60 years.

To give the construction enough buoyancy, it was planned to install an extra floater unit. Research and studies concluded that use of concrete with lower density would solve the problem. During the construction period, there was developed and utilised a new concrete were natural coarse aggregate was partly replaced by LWA (Light Weight Aggregate). The MND (Modified Normal Density) concrete has a density reduction of about 10%, but still maintain most of the mechanical properties from ND (Normal Density) concrete.

Experience

The mix design for Heidrun TLP has been developed over several years, starting some 10 years ago. The reduced weight is achieved by replacing the natural coarse aggregate with lightweight materials made of expanded clay. The other constituents are the same as used for normal density (ND) concrete of high strength.

Why expanded clay?

A large displacement is necessary to achieve the buoyancy required for a TLP of this size. Buoyancy members of steel must withstand large hydrostatic pressures. A high strength concrete shell which can take the water pressure in direct compression is ideal for such exposure.

A concrete hull will be heavier than a steel hull. Consequently, the necessary buoyancy and displacement need to be increased. The mooring tether forces tend to increase with the displacement.

However, more important is the location of the centre of gravity. For a concrete platform, this will be at about the same elevation as the resultant of the first order wave forces. Thus, the tether forces from the concrete hull are significantly lower than those from a steel hull which are to carry the same topside weight.

Concrete material for the TLP hull has several merits. Main areas of steel TLP, the node intersection between the pontoon and the columns and the tether attachments to the hull, are exposed to severe fatigue.