EXPANDED CLAY IN FLOOR APPLICATIONS

Expanded clay is used extensively in floors, both loose on its own or mixed with binders (cement, lime, resins, etc…).

To fully exploit the insulating and lightness characteristics of granular expanded clay, the material should be laid loose on the floor and simply levelled to the thickness desired (with slight falls if required). If the top surface is not to be walkable, it can be left as it is, otherwise it must be covered with a layer of another material (various types of panel, a screed, a non-structural or structural floor slab, or plant growth soil).

Expanded clay binds easily with cement to give a lightweight concrete floor with better mechanical strength as compared to the loose product. These concrete mixes can be prepared using ordinary batchers or mixers.

This material can also be mixed with other binders, such as hydraulic lime and resins.

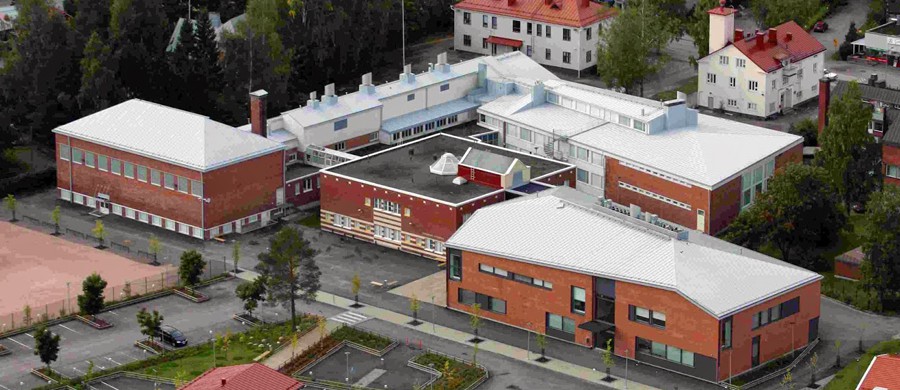

ROOFS

When used on roofs, expanded clay ensures that the necessary degree of insulation combined with high thermal inertia (the two indispensable requirements for comfortable winter and summer habitation) will be met. Due to its lightweight characteristics, it can be laid to a considerable thickness without excessively loading the structure.

In its loose form, after having been consolidated on its top surface, or after it being bound with cement, expanded clay can be used as an insulation layer incorporating falls for rainwater run-off, or as ballast on top of a waterproof layer. If it is to take an impermeable membrane, a screed will be required. It can also be applied on roof pitches if it consolidated with cement.

Expanded clay can also be used in roof voids as a durable insulating layer of high compressive strength that is impenetrable to rodents or birds. Its excellent thermal inertia makes it particularly effective to reduce summer overheating. If the roof void is not walkable, the product can be laid loose or placed in bags placed directly on the floor. If the roof void is to be accessible, the surface can be slurred or covered with wood-cement slabs; if it is to be walkable, the product can be mixed with cement and topped with a screed.

LANDSCAPING

DRY SCREEDS

Expanded clay in granular form is used as a continuous lightweight levelling, compensating, and insulating screed. It does not require compaction and can be applied in thicknesses of 1 cm and above. When used as part of a screening system, it can be finished by laying specific types of panelling (SmartPly OSB, plasterboard, fibreboard, chipboard, etc.) to take the flooring

BASE LAYER FOR FLOOR FINISH

Due to its low specific weight, expanded clay can be laid to considerable thicknesses, and incorporate electrical and water services whilst keeping the structural loading low the porous nature of the expanded clay granules gives excellent thermal installation and improves acoustic insulation. To lay the floor finish, a lightweight insulating top screed is required, either using one of the mixes in the premix expanded clay product range or a traditional sand/cement mix.

LIGHTWEIGHT INSULATING BACKFILL INCLUDING FOR REFRACTORY PURPOSES

New construction often requires a backfill material that is stable, durable, lightweight, and non-combustible. This often the case for structural purposes in the refurbishment of old buildings, e.g. as a lightweight fill on top of old structural vaults and different types of floors and decks, etc. Expanded clay is extremely well-suited to these applications. It can also be used as backfill in proximity to structural elements that are combustible (such as timber stairs and suspended floors). It is also extensively used as an insulation material in civil and industrial construction as fire protection, for making safe active or redundant cisterns and storage tanks, for laying underground pipelines, and as insulation at high temperatures, including of refractory type.

GROUND FLOORS

INSULATION FOR FOUNDATIONS AND EARTH RETAINING WALLS

The underground parts of buildings must be adequately insulated to reduce heat loss into the ground. Expanded clay can be used for this purpose in civil, industrial, and zoo technical buildings, and as a hard-core layer with effective insulating characteristics below most floors, including industrial floors, refrigerated cold stores, or floors that incorporate heating pipework. For these applications, it is recommended to use “hydrophobic” expanded clay, which is also very effective against rising damp or as insulation and drainage behind vertical earth-retaining structures.